-

Welcome to Elio Owners! Join today, registration is easy!

You can register using your Google, Facebook, or Twitter account, just click here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Elio Alternate Project Is Underway.

- Thread starter Mark BEX

- Start date

And Mark, you were wondering why your front end was 100% spot on.

Well you just found something that wasn't, it makes up for the front end fit and finish.

Everything has a weak spot, you just found the balance piece.

This make sense???

Well you just found something that wasn't, it makes up for the front end fit and finish.

Everything has a weak spot, you just found the balance piece.

This make sense???

Velhartice

Elio Enthusiast

As of Yesterday;

Don't panic about the delay Guys, I have been trying to work out a simpler, cheaper design method for suspension production using a different spindle (also called 'upright' or 'steering knuckle', depending on Country), and it didn't work out

Was completely my fault as I counted the number of drive splines on the CV outer joint to the hub splines 3 days ago, same number, 21 teeth, great, grabbed some used spindles complete with with hubs 2 days ago, then discovered yesterday that the spline number was indeed the same, but the diameter was one lousy millimeter different (0.040"), I couldn't believe it. My bad, I should have been more careful in my initial checking.

As of today;

I might be ok after all. The new spindles (also called 'uprights' or 'steering knuckles') I desire to use were disappointing, re; the mistake I made with the CV shaft spline diameter.

So after staring at them for a few minutes this morning, I realised the wheel hubs themselves looked similar, and pressed both sets apart. They are almost identical in dimensions, other than the donor car hub's shaft boss is 2mm/0.080" larger diameter (where it's pressed into the wheel hub bearing).

So around the corner to my lathe guy, and he promptly took the 2mm off for me, see red arrows in before/after picture. Took a whole 5 minutes.

Ran out of time tonight to see if it will work, but I'll know in the morning if it fits into the new spindles

View attachment 24731

No panic here.

Thank you for the continuous updates, they are much appreciated.

Just to save Mark some time, he responded to my private message with something I thought was interesting to our engineers. Mark says the rear shell on his Lotus 7 (below) cost him $115(USD?) to have built locally. Tells me one reason products can come out of China as fast as they do. Lotus 7 kits and individual interest exists all over the world, as a niche but ever lasting hobby craft.

2 days ago:

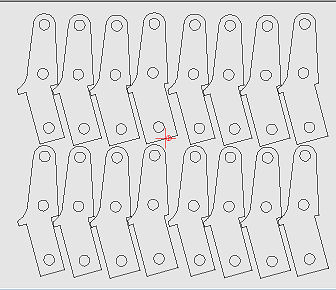

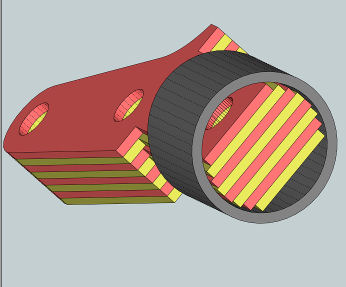

I am making some adapters hat will resolve a few suspension placement problems easily.

There are actually only 2 thick adapters here, they are each built up from 8 thin plates, why? Because they fit into a tube, and with laser these days, it's very easy way to do it this way rather than cutting one thick piece and then grinding or turning it down to fit in the tube.

Yesterday:

I also decided to move the entire crossmember, suspension, engine and driveline 100mm/4" further back which took up most of yesterday, just a mess, so no pictures worth taking of that ...

Today:

So my plates were lasered today, put them together, they fit into the round tube just as planned, bit of weld and now I have the 2 adapters I need to move forward. You will see their purpose in a few days.

I am making some adapters hat will resolve a few suspension placement problems easily.

There are actually only 2 thick adapters here, they are each built up from 8 thin plates, why? Because they fit into a tube, and with laser these days, it's very easy way to do it this way rather than cutting one thick piece and then grinding or turning it down to fit in the tube.

Yesterday:

I also decided to move the entire crossmember, suspension, engine and driveline 100mm/4" further back which took up most of yesterday, just a mess, so no pictures worth taking of that ...

Today:

So my plates were lasered today, put them together, they fit into the round tube just as planned, bit of weld and now I have the 2 adapters I need to move forward. You will see their purpose in a few days.

To bad Elio Marketing, I mean Motors, didn’t have any designers/engineers/technicians/fabricators on their R&D team that could have designed, engineered, and fabricated the Elio prototype in house (similar to Team Arcimoto members and Team BEX) rather than a high salaried board of director team of marketers. We may have been driving our Elio’s the last 3 years.

84mpg

Elio Addict

Yep Rickb..... you said a mouthful of truth right there.

There was that bunch of fellas from up North early on that was kind of prototyping.To bad Elio Marketing, I mean Motors, didn’t have any designers/engineers/technicians/fabricators on their R&D team that could have designed, engineered, and fabricated the Elio prototype in house (similar to Team Arcimoto members and Team BEX) rather than a high salaried board of director team of marketers. We may have been driving our Elio’s the last 3 years.

If you were Paul following this plan of yours, how much are you going to price your common and upgraded model?Just my creative thinking, but, I think Elio should have marketed two streams. One version as a cool upgraded bench built, with all upgrades, open wheel (mileage be damned), custom rim (spokes and mags options) and a turbo. Also signature authentication papers, special VIN, and some other kinds of body mods to make it stand out from the common model. The common would not have the Turbo or other options available. This difference keeps the upgraded one distinctive. Kind of like a Shelby Mustang versus a floor model.

This upgraded one would be built in lots of ten (or more) and auctioned individually. Then every n-th unit of the lot is a common model sold to the reservationists at the promised price. Then as Elio proves to have a profit and thousands of back orders, investment would be more available. Then later they could complete their crash testing and then finally upgrade manufacturing to higher levels. They would just have to carefully manage the ratio of what is auctioned vs the common model sales, carefully adjusting the ratio to retain a predictable profit margin.

Predictable profits builds confidence. Confidence attracts investors. Probably could prove profit margins would go up with investment, not down.

Don't know how that would work for something imported. But by the Meccanica model, you just assemble in the country where sold and import 100% of the parts from China.

In the USA, last I investigated, depending on the state, building less than 12/mo is a custom car shop, are individually inspected at a DMV and licensed. Then sold almost as if it was a used car. Above that other certs are required.

Jeepster here in Phoenix was doing that in the '90s with VW engines at around 20-80 vehicles each month. (Note: Engine emissions already certified in the US)

Well, in the end EM is just NOT up to the task. Got too way ahead of themselves from their original KISS concept of off-the-shelf parts and the whole project got away from them.

-- Arak

Last edited:

I'm very happy to be moving forward again, now I seem to be past the crossmember and related setup issues.

I am using McPherson strut front suspension as it's the fastest way to get a drive'able prototype vehicle, which is most important at the moment. It does NOT mean I will use them for production, but I do have some ideas surrounding them that I will try later, as they are the simplest and cheapest option.

The inside picture kind of looks the same from a few weeks ago, but is a completely different car now, and the entire front assembly has actually been moved backwards 100mm/4" ..

I am shy about posting messy work pictures, but I ran out of time today and no work for the next 3 days as it's Mayday holiday week, and I have been ordered to go camping on Sunday and Monday.

You see the usual suspects in the picture, welder, compressor, spirit level, grinding discs etc ...

It's a bit of a mess of tubes, but note they all won't be there later, and I always have them too long as it's easy to cut them shorter later, but not so easy to add to them if too short ...

I am using McPherson strut front suspension as it's the fastest way to get a drive'able prototype vehicle, which is most important at the moment. It does NOT mean I will use them for production, but I do have some ideas surrounding them that I will try later, as they are the simplest and cheapest option.

The inside picture kind of looks the same from a few weeks ago, but is a completely different car now, and the entire front assembly has actually been moved backwards 100mm/4" ..

I am shy about posting messy work pictures, but I ran out of time today and no work for the next 3 days as it's Mayday holiday week, and I have been ordered to go camping on Sunday and Monday.

You see the usual suspects in the picture, welder, compressor, spirit level, grinding discs etc ...

It's a bit of a mess of tubes, but note they all won't be there later, and I always have them too long as it's easy to cut them shorter later, but not so easy to add to them if too short ...