No, but it does come with a lot of pain medication.I got the email. Love the seat, wonder if it comes in leather

-

Welcome to Elio Owners! Join today, registration is easy!

You can register using your Google, Facebook, or Twitter account, just click here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Real P5 ?

- Thread starter WilliamH

- Start date

Ekh

Elio Addict

2 so far. This is not the test-stand engine. That's from Paul's Fireside Chat a week or so back.Isn't this the same engine on the test stand?

How many engines have they built?

it was reported by EM that the first engine (the one in the video) has been run extensively and has been disassembled for close inspection .... the motor going in the P5 is a different one .... no clue how many they may have, they have acknowledged having 2

Look at the right hand opening where the suspension sticks through. It looks like the flare of the P4 around the opening is gone. I was afraid of that. This is in keeping with the CAD drawing that had the opening covered up with suspension parts sticking out through holes. The flare looked good. It looked sporty. With gas prices so low, it may be a good idea to retain the stylish features. Anything for the almighty 84 mpg.

[Broken External Image]

[Broken External Image]

Notice the two L shaped metal pieces that look like they will be welded to the "frame" on the left side and I assume the left body panel will be glued to them. It looks like there will be much room at the front of the engine but very cramped at the back were the working components are, such as the alternator, AC compressor, belt and other parts. These are the items that need attention, not the exhaust manifold.

When the picture is enlarged by clocking on it, you can see the cam gear cover is made of see through plastic and you can see the cam gear inside. This was visible in the video showing the engine running on the dyno. Yes, this appears to be the same engine.

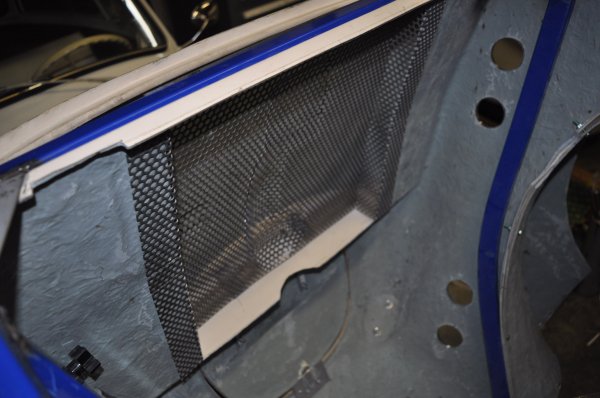

This has "screen" mesh welded in places and this is the P5 which is suppose to be identical to the production model. Does this mean there will be "screen" mesh in the production units?

When the picture is enlarged by clocking on it, you can see the cam gear cover is made of see through plastic and you can see the cam gear inside. This was visible in the video showing the engine running on the dyno. Yes, this appears to be the same engine.

This has "screen" mesh welded in places and this is the P5 which is suppose to be identical to the production model. Does this mean there will be "screen" mesh in the production units?

Last edited:

slinches

Elio Addict

True ... unless you install a turbo.

And it's likely this engine is using near identical hardware to the first test engine. PE mentioned they were the same design. I wouldn't be surprised if they are reusing a few of the dummy parts from that engine either. Where I work, we often use mock up 3D printed plastic hardware for fit checks and development testing while we're waiting for castings to arrive.

And it's likely this engine is using near identical hardware to the first test engine. PE mentioned they were the same design. I wouldn't be surprised if they are reusing a few of the dummy parts from that engine either. Where I work, we often use mock up 3D printed plastic hardware for fit checks and development testing while we're waiting for castings to arrive.

Last edited:

DAVID BROWER

Elio Addict

I NOTICED THE USE OF PERFORATED METAL IN PARTS OF THE P-5 BODY .

IT IS EASY TO BEND & FORM . IT CAN BE GLASSED OVER ONCE THE SHAPE IS RIGHT .

I APPROVE OF THIS BUILD TECHNIQUE .

I AM USING THE SAME STUFF ON SOME PARTS OF THE

MESSERSCHMITT TIGER I AM BUILDING .

HERE IS MY HAND FORMED TRUNK FLOOR WITH MOTOR CLEARANCES .

IT IS EASY TO BEND & FORM . IT CAN BE GLASSED OVER ONCE THE SHAPE IS RIGHT .

I APPROVE OF THIS BUILD TECHNIQUE .

I AM USING THE SAME STUFF ON SOME PARTS OF THE

MESSERSCHMITT TIGER I AM BUILDING .

HERE IS MY HAND FORMED TRUNK FLOOR WITH MOTOR CLEARANCES .

[Broken External Image]

This looks like a clutch and manual transmission. Is the P5 suppose to be automatic or manual? More mesh is visible. One thing I can think mesh would be good for, is gluing things (like composite panels) to them. The housing on the right has a pedal hanging down from under it. I guess this is the clutch pedal and the housing is for mounting one end of the clutch cable and the brake master cylinder.

This looks like a clutch and manual transmission. Is the P5 suppose to be automatic or manual? More mesh is visible. One thing I can think mesh would be good for, is gluing things (like composite panels) to them. The housing on the right has a pedal hanging down from under it. I guess this is the clutch pedal and the housing is for mounting one end of the clutch cable and the brake master cylinder.

Yes. Perforated metal is the correct term. Thanks.I NOTICED THE USE OF PERFORATED METAL IN PARTS OF THE P-5 BODY .

IT IS EASY TO BEND & FORM . IT CAN BE GLASSED OVER ONCE THE SHAPE IS RIGHT .

I APPROVE OF THIS BUILD TECHNIQUE .

I AM USING THE SAME STUFF ON SOME PARTS OF THE

MESSERSCHMITT TIGER I AM BUILDING .

HERE IS MY HAND FORMED TRUNK FLOOR WITH MOTOR CLEARANCES .

View attachment 7035

View attachment 7036

P. S. Nice work.