OK, back to the engine.....

thank you .... thank you very much ..

Welcome to Elio Owners! Join today, registration is easy!

You can register using your Google, Facebook, or Twitter account, just click here.OK, back to the engine.....

OK, back to the engine.....torquey (new word?) engines can be lots of fun, because their high-torque output peaks at rpms near where the HP is beginning to really get going, and that makes for a real sporty engine, top to bottom ends.

Just think if my flat-head V-8 '49 Ford (230cu.in.,100hp) had made horsepower like that.....we thought with three of those old Stromberg 97 carbs we were something else. Probably a good thing considering the tires I had in those days. They turned to rags pretty easily.

On Mar 1, 2015, I sent the following email to EM:

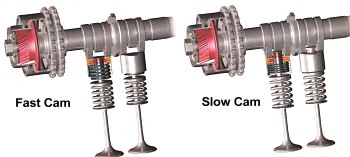

Tech Talk v39 says (for the intake valve where the two step valve is located) there will be a center lobe for one valve step and there will be two other lobes (one on each side) for the other valve step. This makes three lobes for that valve.

http://www.eliomotors.com/tech-talk-v39-the-engine-part-2/

When I look at the elio power plant animation, I can only find two valves and a curved top "lifter" they press against. This looks like only two lobes are used and the two step is achieved by a 90 degree rotation of the "lifter".

One indicates three lobes and the other indicates two lobes. Both pieces of information are from Elio Motors. Am I missing something?

Thank you.

"One of the potential technology features of the Elio engine is the two-step valve lift system (VVA) which uses switching tappets. The two-mode tappets allow switching between two different valve lift profiles which allows the engine to change its airflow capacity. One mode increases airflow capacity for more torque/power in city driving. The other mode decreases airflow to reduce pumping work during light load operation such as highway driving.

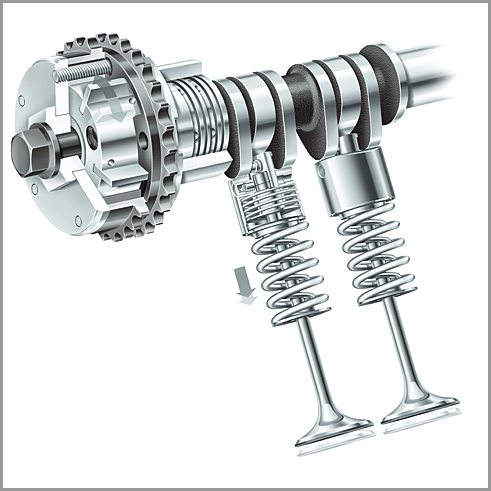

The switching tappet consists of two nested housings, the inner and outer housing. The inner housing is actuated by the center cam lobe while the outer housing is actuated by lobes on either side of the center lobe. The outer housing presses against a lost motion spring when the hydraulic actuation circuit is at low pressure. In this mode the center lobe determines the valve lift. Both housing parts can be linked by means of a coupling mechanism, a high pressure hydraulic chamber. In the locked condition, the high lift is transmitted via the outer housing to the valve. As in the standard tappet, valve lash adjustment can be by hydraulic or mechanical means.

The Elio engine uses a cooled Exhaust Gas Recirculation (EGR) system. The EGR system will be used to improve fuel consumption of the engine by reducing pumping losses and lowering peak cylinder temperatures which reduces NOx emissions. When the EGR is cooled it further reduces combustion temperatures and reduces engine knocking. This enables the engine to have a high mechanical compression ratio which helps improve fuel economy and performance. The EGR system is controlled by the ECU and will allow a specific amount of EGR into the intake manifold to be distributed into the combustion chamber."

Tech Talk V39 - http://www.eliomotors.com/tech-talk-v39-the-engine-part-2/

I DO like answers with references...

These diagrams are from a Porsche system however Elio Motors will be using essentially the same setup on each of the three intake valves. The ECU controls a valve to allow oil pressure to either lock or unlock the center pin so the valve can be activated by the dual outer cam lobes or the inner cam lobe which allows the intake valve to have two different lift/timing configurations depending on the load.

These diagrams are from a Porsche system however Elio Motors will be using essentially the same setup on each of the three intake valves. The ECU controls a valve to allow oil pressure to either lock or unlock the center pin so the valve can be activated by the dual outer cam lobes or the inner cam lobe which allows the intake valve to have two different lift/timing configurations depending on the load.

earlier, there was some discussion that if the motor proved to have more than 55 hp, they may be able to adjust the gearing so as to get a bit better mileage .... not being up on such things, I can see how that might be possible but have no way of knowing