eddie66

Elio Addict

- Joined

- Apr 12, 2014

- Messages

- 1,341

- Reaction score

- 4,069

November 3, 2014

Machining of Individual Components Complete, Engine Prototype Testing Next

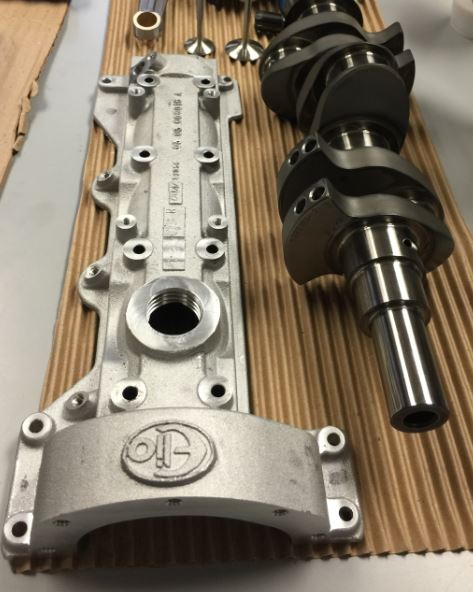

In part one of this series on Elio engine development we discussed the need to develop a new engine from the ground up. As we dove deeper into the vehicle’s design, it was clear the Geo Metro engine upon which we hoped to base our design would not provide the right balance of power and fuel economy.Our engine development partner, IAV, went back to the drawing board and was able to configure a new engine design, while sticking to one of Elio Motors basic tenets for the company – use existing technology, but package it in a way that still meets the company’s performance and fuel efficiency targets. Even though the company is using tried and true technology, we still needed to ensure that each individual component is engineered and machined to rigorous specifications. Each component must be tested and validated individually, then packaged together as one working prototype.

None of this can be done using mass production techniques, so it is one of the more meticulous portions of the vehicle development process. It is also one of the most important portions of the vehicle development process, as the engine is one of the keys to meeting our fuel efficiency and performance criteria. Ultimately, how this engine performs is going to be a crucial element driving our customer satisfaction. Therefore, due diligence and proper development are essential to a successful engine program launch.

Machining of Individual Components Complete, Engine Prototype Testing Next

In part one of this series on Elio engine development we discussed the need to develop a new engine from the ground up. As we dove deeper into the vehicle’s design, it was clear the Geo Metro engine upon which we hoped to base our design would not provide the right balance of power and fuel economy.Our engine development partner, IAV, went back to the drawing board and was able to configure a new engine design, while sticking to one of Elio Motors basic tenets for the company – use existing technology, but package it in a way that still meets the company’s performance and fuel efficiency targets. Even though the company is using tried and true technology, we still needed to ensure that each individual component is engineered and machined to rigorous specifications. Each component must be tested and validated individually, then packaged together as one working prototype.

None of this can be done using mass production techniques, so it is one of the more meticulous portions of the vehicle development process. It is also one of the most important portions of the vehicle development process, as the engine is one of the keys to meeting our fuel efficiency and performance criteria. Ultimately, how this engine performs is going to be a crucial element driving our customer satisfaction. Therefore, due diligence and proper development are essential to a successful engine program launch.