zelio

Elio Addict

Elio Motors Tech Talk v33

View this email in your browser

Want to see some Elio technology in action? Head to the race track this weekend!

One of the coolest things about auto racing – aside from the fast cars and competition – is that it serves as a living, breathing laboratory for the auto industry. The technology seen on the track often ends up in showrooms and then driveways as new innovations are tested and then brought to market.

It makes sense. Racing components are selected by a simple philosophy: Are they lighter, and do they perform better? Obviously, those attributes are important to Elio Motors. So, having supplier partners such as Peterson Spring actively involved in auto racing is an important aspect in maximizing vehicle efficiency and maintaining performance standards.

Peterson Spring is bringing its expertise to the Elio team in two important areas. First, it provides high-tech suspension springs and shocks to the Elio suspension. Second, it is providing engine valve springs to improve the engine’s ability to convert fuel into power.

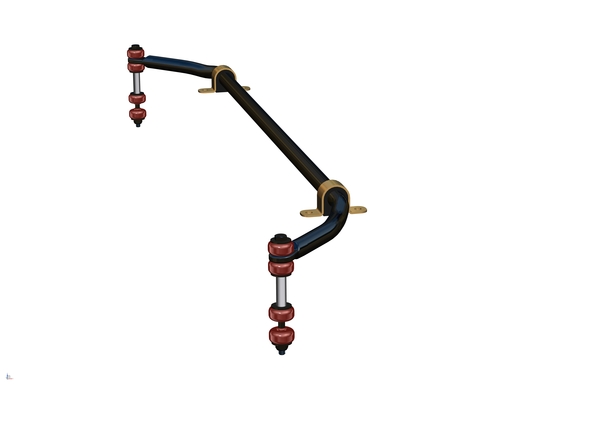

Performance Shock Absorber Assembly

Formed Stabilizer Bar

In both of these areas, weight savings is one of the most important attributes that Peterson Spring brings to the table. Why do weight savings matter? Reducing weight, packaging, and the space required to push a vehicle through the air, all directly increase fuel MPG. With an industry altering goal of 84 MPG, every ounce saved makes a difference.

Peterson Spring likens its technology to the computer industry. In the 1960s, computers took up entire rooms, but their computing power was limited to basic computation. Through innovation, a modern, more powerful computer can now fit into the palm of your hand. Applying this concept to springs, Peterson Spring possesses the ability to reduce the size of a spring and shock by using state of the art materials and race-type processing. This yields an end product that provides a competitive edge to Elio Motors.

Underhood Springs Convert Fuel to Power, Reduce Emissions

While the suspension springs are visible parts of the Elio design, Peterson Spring brings innovation to engine technology as well. Peterson Spring brings the ability to manufacture ultra-efficient and high RPM engine valve springs and other valve train components. Reduced mass or weight plays a significant role in improving the performance of the engine. Allowing an engine valve spring to rev higher improves the engine's ability to convert fuel into power, while also reducing emissions.

View attachment agallery.mailchimp.com_24b371802c83d81776b06aa68_images_7cb1fd2d6b8f4724babd24ff66d177f42fd541.jpg

High Performance Valve Train

Think about how high a dragster revs the engine prior to the green light. Race engines commonly hit more than 11,000 RPM. This harsh environment requires improved thermal efficiency and performance. Passenger vehicle engines are trending in the direction of higher RPMs in smaller engines every model year. Previous limitations didn't allow for the standard automotive engine to achieve this level of performance. Peterson Spring developed processing, tested in race markets and worked to integrate that technology into the automotive market. The Elio vehicle will be utilizing the latest in engine valve train technology and performance selected by Peterson Spring engineers.

Beehive Valve Spring

While the Elio probably won’t win a whole lot of drag races, it will still reach a top speed of more than 100 MPH (though we highly recommend staying within posted speed limits to keep your driving record clean!). The technology developed by Peterson Spring through its racing activities is a big reason why Elio Motors is making great strides in achieving its price, performance and fuel efficiency goals.

Copyright © 2014 Elio Motors, All rights reserved.

You signed up to receive updates from Elio Motors where you filled out a form including your name and email address!

Our mailing address is:

Elio Motors

2942 North 24th Street

Suite 114-700

Phoenix, AZ 85016

Add us to your address book

View this email in your browser

Want to see some Elio technology in action? Head to the race track this weekend!

One of the coolest things about auto racing – aside from the fast cars and competition – is that it serves as a living, breathing laboratory for the auto industry. The technology seen on the track often ends up in showrooms and then driveways as new innovations are tested and then brought to market.

It makes sense. Racing components are selected by a simple philosophy: Are they lighter, and do they perform better? Obviously, those attributes are important to Elio Motors. So, having supplier partners such as Peterson Spring actively involved in auto racing is an important aspect in maximizing vehicle efficiency and maintaining performance standards.

Peterson Spring is bringing its expertise to the Elio team in two important areas. First, it provides high-tech suspension springs and shocks to the Elio suspension. Second, it is providing engine valve springs to improve the engine’s ability to convert fuel into power.

Performance Shock Absorber Assembly

Formed Stabilizer Bar

In both of these areas, weight savings is one of the most important attributes that Peterson Spring brings to the table. Why do weight savings matter? Reducing weight, packaging, and the space required to push a vehicle through the air, all directly increase fuel MPG. With an industry altering goal of 84 MPG, every ounce saved makes a difference.

Peterson Spring likens its technology to the computer industry. In the 1960s, computers took up entire rooms, but their computing power was limited to basic computation. Through innovation, a modern, more powerful computer can now fit into the palm of your hand. Applying this concept to springs, Peterson Spring possesses the ability to reduce the size of a spring and shock by using state of the art materials and race-type processing. This yields an end product that provides a competitive edge to Elio Motors.

Underhood Springs Convert Fuel to Power, Reduce Emissions

While the suspension springs are visible parts of the Elio design, Peterson Spring brings innovation to engine technology as well. Peterson Spring brings the ability to manufacture ultra-efficient and high RPM engine valve springs and other valve train components. Reduced mass or weight plays a significant role in improving the performance of the engine. Allowing an engine valve spring to rev higher improves the engine's ability to convert fuel into power, while also reducing emissions.

View attachment agallery.mailchimp.com_24b371802c83d81776b06aa68_images_7cb1fd2d6b8f4724babd24ff66d177f42fd541.jpg

High Performance Valve Train

Think about how high a dragster revs the engine prior to the green light. Race engines commonly hit more than 11,000 RPM. This harsh environment requires improved thermal efficiency and performance. Passenger vehicle engines are trending in the direction of higher RPMs in smaller engines every model year. Previous limitations didn't allow for the standard automotive engine to achieve this level of performance. Peterson Spring developed processing, tested in race markets and worked to integrate that technology into the automotive market. The Elio vehicle will be utilizing the latest in engine valve train technology and performance selected by Peterson Spring engineers.

Beehive Valve Spring

While the Elio probably won’t win a whole lot of drag races, it will still reach a top speed of more than 100 MPH (though we highly recommend staying within posted speed limits to keep your driving record clean!). The technology developed by Peterson Spring through its racing activities is a big reason why Elio Motors is making great strides in achieving its price, performance and fuel efficiency goals.

Copyright © 2014 Elio Motors, All rights reserved.

You signed up to receive updates from Elio Motors where you filled out a form including your name and email address!

Our mailing address is:

Elio Motors

2942 North 24th Street

Suite 114-700

Phoenix, AZ 85016

Add us to your address book