Elio Motors Momentum v97

When you picture an entry in an elementary school science fair, you might think of a papier-mâché volcano. It may not be the most original display, but it demonstrates a chemical reaction behind the scenes that works to highlight the final product. Most automakers display their final product without providing a look at the process. Elio Motors is different: we have decided to include our supporters on our journey to produce a fuel-efficient, affordable, safe, and American made vehicle. Through the course of our journey, significant changes have been made to the Elio in order to accomplish our goals. Today, we will take a look at the iterative improvements we have made to the wheel fairings and the reasons behind these improvements.

During the prototype phase of the project, we showed the evolution of our vehicle by highlighting the improvements we had made to each ensuing prototype. Each iteration of the Elio showcased improvements, both subtle and pronounced, to the design of the vehicle. Perhaps the most notable change through the prototype phase was the enhanced aerodynamics between the P3 and the P4. The P3 featured outboard headlamps and fenders similar to the Plymouth Prowler. While aesthetically pleasing to some, these features compromised our mileage goals. Thus, substantial changes were made to the design, as can be first seen on the P4. The P4 showed in-boarded headlamps and full-skirt fenders.

The improvements to the design have continued. Through the use of Computer Aided Engineering (CAE) our engineers are able to evaluate which shape and design of the wheel fairings will allow for optimum fuel efficiency. The wheel fairings seen on the P5 and E1c vehicles were packaged to a 175 mm front wheel width. While this iteration of the wheel fairings was an improvement to those seen on the P4, further enhancements were necessary to improve the drag characteristics of the vehicle.

Utilizing Computational Fluid Dynamics (CFD) our engineers are able to identify the ideal fairing shape and size. Ultimately, four different designs were tested. These concepts took advantage of the smaller 135 mm front tire width.

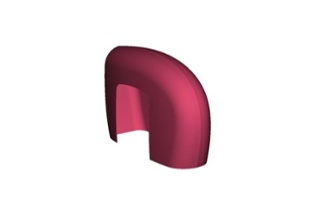

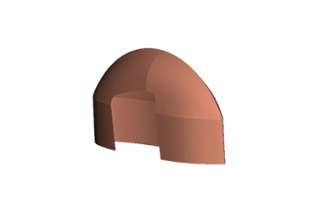

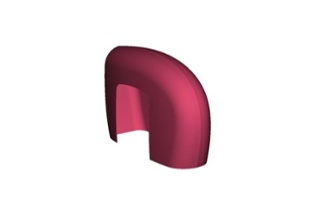

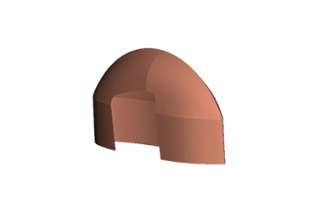

Concept 1- The first concept fairing essentially shrunk the P5/E1c design, and rounded the corners and removed any protrusions exposed to the airstream. These changes resulted in a 14% improvement in drag.

Concept 2- This concept reduced the width and lengthened the overall fairing to help split and reattach the airflow around the fairing for a further reduction in drag force. This resulted in an 18% improvement.

Concept 3- The third concept design took the flow separation and reattachment even further for a large improvement in drag force reduction. However, the fairing was so long that opening the vehicle door would be hindered.

Concept 4- Finally, the fourth design was modified from the Concept Fairing 2 with a minimum overall width, parabolic side wall profile, and an overall length that did not hinder the vehicle’s door. These refinements resulted in a 34% overall drag reduction from the P5/E1c design.

By utilizing both CAE and CFD our engineers are able to save a significant amount of resources and time while making critical enhancements to our vehicle. The wheel fairings are but one example of our dedication to building the best possible vehicle.

We appreciate having our supporters along with us on our journey to alter the course of transportation. We will continue to give you an inside look at the process of bringing a revolutionary vehicle to market.

*MSRP excludes destination/delivery charges, taxes, title, registration, and options/installation.

Certain statements in this email including, but not limited to, statements related to anticipated commencement of commercial production, targeted pricing and performance goals, and statements that otherwise relate to future periods are forward-looking statements. These statements involve risks and uncertainties, which are described in more detail in the Company’s periodic reports filed with the SEC, specifically the most recent reports which identify important risk factors that could cause actual results to differ from those contained in the forward-looking statements. Forward-looking statements are made and based on information available to the Company on the date of this email. Elio Motors assumes no obligation to update the information in this email.

When you picture an entry in an elementary school science fair, you might think of a papier-mâché volcano. It may not be the most original display, but it demonstrates a chemical reaction behind the scenes that works to highlight the final product. Most automakers display their final product without providing a look at the process. Elio Motors is different: we have decided to include our supporters on our journey to produce a fuel-efficient, affordable, safe, and American made vehicle. Through the course of our journey, significant changes have been made to the Elio in order to accomplish our goals. Today, we will take a look at the iterative improvements we have made to the wheel fairings and the reasons behind these improvements.

During the prototype phase of the project, we showed the evolution of our vehicle by highlighting the improvements we had made to each ensuing prototype. Each iteration of the Elio showcased improvements, both subtle and pronounced, to the design of the vehicle. Perhaps the most notable change through the prototype phase was the enhanced aerodynamics between the P3 and the P4. The P3 featured outboard headlamps and fenders similar to the Plymouth Prowler. While aesthetically pleasing to some, these features compromised our mileage goals. Thus, substantial changes were made to the design, as can be first seen on the P4. The P4 showed in-boarded headlamps and full-skirt fenders.

The improvements to the design have continued. Through the use of Computer Aided Engineering (CAE) our engineers are able to evaluate which shape and design of the wheel fairings will allow for optimum fuel efficiency. The wheel fairings seen on the P5 and E1c vehicles were packaged to a 175 mm front wheel width. While this iteration of the wheel fairings was an improvement to those seen on the P4, further enhancements were necessary to improve the drag characteristics of the vehicle.

Utilizing Computational Fluid Dynamics (CFD) our engineers are able to identify the ideal fairing shape and size. Ultimately, four different designs were tested. These concepts took advantage of the smaller 135 mm front tire width.

Concept 1- The first concept fairing essentially shrunk the P5/E1c design, and rounded the corners and removed any protrusions exposed to the airstream. These changes resulted in a 14% improvement in drag.

Concept 2- This concept reduced the width and lengthened the overall fairing to help split and reattach the airflow around the fairing for a further reduction in drag force. This resulted in an 18% improvement.

Concept 3- The third concept design took the flow separation and reattachment even further for a large improvement in drag force reduction. However, the fairing was so long that opening the vehicle door would be hindered.

Concept 4- Finally, the fourth design was modified from the Concept Fairing 2 with a minimum overall width, parabolic side wall profile, and an overall length that did not hinder the vehicle’s door. These refinements resulted in a 34% overall drag reduction from the P5/E1c design.

By utilizing both CAE and CFD our engineers are able to save a significant amount of resources and time while making critical enhancements to our vehicle. The wheel fairings are but one example of our dedication to building the best possible vehicle.

We appreciate having our supporters along with us on our journey to alter the course of transportation. We will continue to give you an inside look at the process of bringing a revolutionary vehicle to market.

*MSRP excludes destination/delivery charges, taxes, title, registration, and options/installation.

Certain statements in this email including, but not limited to, statements related to anticipated commencement of commercial production, targeted pricing and performance goals, and statements that otherwise relate to future periods are forward-looking statements. These statements involve risks and uncertainties, which are described in more detail in the Company’s periodic reports filed with the SEC, specifically the most recent reports which identify important risk factors that could cause actual results to differ from those contained in the forward-looking statements. Forward-looking statements are made and based on information available to the Company on the date of this email. Elio Motors assumes no obligation to update the information in this email.